1. High-power heating plate can ensure stable heating temperature.

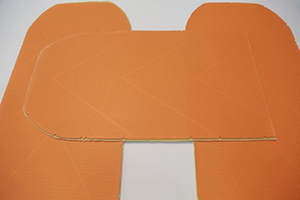

2. One-button frame feeding, automatic frame pressing, reducing labors and ensuring compound accuracy.

3. Equipped with the leather lamination machine control system independently developed by Richpeace.

4. The top layer adopts a heating plate to ensure heating evenly; the bottom layer adopts a high-density elastic material support plate to ensure even pressure, higher bonding strength and better compounding effect.

5. 10-inch HD one-touch control panel, easy and fast to operate.

6. The top and bottom heating plates adopt hydraulic system to ensure stable compound pressure.

7. Suitable for all kinds of net film hot-melt adhesive compounding, no colloid overflow, no dirt adhesion, and ensuring the product smooth and beautiful.

8. Equipped with safety protection light curtain, preventing human body from damage caused by the heating plate during operation.

| Type of laminating | Hot melt | Material Width | 950mm (can be customized) |

| Type of clamp frame | Pneumatic | Air Pressure | 0.6MP |

| Heating time | 10S (adjustable) | Voltage | 3 phase 380V/50Hz |

| Max. efficiency | 25 s/pc. | Power | 15kW |